Our electromagnetic flowmeters are mainly used in the food and beverage industry. They work according to the Faraday principle. Unlike all other electromagnetic flowmeters on the market, they operate in an alternating field (AC) instead of a synchronized DC field. The result is higher measurement dynamics and faster, more precise measurements for dosing the filling time up to 100ms.

Our products

MID-MDS

Modular dosing system (MDS) for filling conductive liquids in filling machines with electromagnetic flowmeters

Application:

Their function is based on conductive liquids (>1µS/cm) in filling machines. These machines are mainly used in the food and beverage industry as well as in the pharmaceutical and fine chemical industries. Among others, dairy products (also with fruit pieces), ketchup, mayonnaise, mustard, sauces, dressings, cleaning and washing agents, medical products (e.g. stomach gels), sterile injection products and cosmetics are measured.

Technische Daten

| Nominal size | DN10 up to DN40 (3/8“ bis zu 1½“) |

| Process connection | Tri-Clamp, hygienic connection for sanitary thread, sterile connections, sterile mini flanges |

| Material | stainless steel, PTFE, Hastelloy |

| Conductivity | >1µS/cm |

| Flow range | 0.25 to 10 ms |

| Repeatability | ±0.1% (depending on flow rate) |

| Process temperature | up to 95°C (203°F) – Cleaning up to 95°C (203°F) |

| Prozessdruck | up to 16 bar |

| Ex-protection | no |

Special features

- shortest dosing times from 100ms possible

- small dimensions of the sensor

- Complete systems for linear and rotary fillers

- Large range of filling quantities with different nominal diameters

- direct control of the dosing valve

- CIP / SIP Cleaning

- Replacement of the flow sensor possible without reprogramming

Batch-Controller

- MID-MDS system for filling control (measurement and valves)

- up to 540 electromagnetic measuring instruments MID and valves

- with communication interface RS232 for communication with the PLC

- MDS terminal for configuration and visualization of the MID-MDS system

- UV 14 converter module for use of user-defined PLC

- MID-PLC for the construction of small filling machines up to 4 devices and 4 valves

Characteristics

- easy cleaning compared to piston filler

- easy adjustment of the filling quantities

- no shear forces are exerted on the product

- Chemistry and pharmaceutical

- Food and beverage

MID-MDS ECO

Compact magnetic inductive flowmeter for filling conductive liquids in filling machines

Application:

Their function is based on conductive liquids (>5µS/cm) in filling machines. These machines are mainly used in the food and beverage industry as well as in the pharmaceutical and fine chemical industries. Among others, dairy products (also with fruit pieces), ketchup, mayonnaise, mustard, sauces, dressings, cleaning and washing agents, medical products (e.g. stomach gels), sterile injection products and cosmetics are measured.

Technical data

| Nominal size | DN2.5 up to DN40 (0.1“ bis zu 1½“) |

| Process connection | Tri-Clamp, hygienic connection for sanitary thread, others on request |

| Material | stainless steel, zirconium oxide |

| Conductivity | >5µS/cm, >20µS/cm for demineralized water |

| Flow range | 1 to 12 m/s |

| Repeatability | up to ±0.1% (depending on flow rate and nominal size) |

| Process temperature | up to 140°C (284°F) – cleaning up to 140°C (284°F) |

| Process pressure | up to 16 bar, higher pressure on request |

| Ex-protection | no |

Special features

- compact design

- small dimensions of the sensor

- large ranges of filling quantities with different diameters

- direct output of volume-proportional pulses

- CIP / SIP Cleaning

Characteristics

- easy cleaning compared to piston filler

- easy adjustment of the filling quantities

- no shear forces are exerted on the product

- Chemistry and pharmaceutical

- Food and beverage

MID-EMF

Compact magnetic inductive flowmeter for filling conductive liquids in filling machines

Application:

The field of application for all electromagnetic flowmeters of the MID-EMF series is the measurement of conductive liquids (>20µS/cm) in dosing and filling systems as well as in continuous flow measurement.

The series comprises the nominal diameters DN3 to DN25 and is available in the pressure stages PN6/8/10. The maximum temperature is 60°C.

Different connections and output signals are available.

Technical data

| Nominal size | DN3 up to DN25 |

| Process connection | thread G3/8″ to G1 1/4″ (Tri-Clamp on request) |

| Material | stainless steel, PVDF, EPDM |

| Conductivity | >20µS/cm |

| Flow range | 0.5 to 10 m/s |

| Repeatability | ±1% (depending on flow rate and nominal size) |

| Process temperature | up to 60°C (140°F) |

| Process pressure | up to 16 bar at 10°C (50°F) |

| Ex-protection | not available |

Special features

- compact design

- small dimensions of the sensor

- large ranges of filling quantities with different diameters

- direct output of volume-proportional pulses, 4-20 mA or 0-10 VDC

Characteristics

- easy cleaning compared to piston filler

- easy adjustment of the filling quantities

- no shear forces are exerted on the product

- Chemistry and pharmaceutical

- Food and beverage

FMD

The dosing mass flow meter extends the range of dosing sensors with a special focus on the dosing of non-conductive media and direct mass dosing.

Application:

The focus is on the measurement of non-conductive liquids with a low gas or solids content. This equipment is also designed for the measurement of oil, distilled water or alkanes. Due to the measuring principle, a direct measurement of the dosing quantity is possible.

Technical data

| Nominal size | DN10, DN15 (3/8“, ½“) |

| Liquid temperature | 0°C to +90°C (32°F to194°F) |

| Process connection |

Tri Clamp according to DIN 32676 Sanitary thread according to DIN 11851 |

| Cleanability | CIP / SIP up to 140°C (284°F) |

Special features

- outstanding fast filling

- Fillings of 10 ml

- very short dosing times > 250 ms

- high accuracy / reproducibility even with small quantities

- high resolution (e.g. DN10 : 63,660 pulses / kg)

- Large selection of filling quantities with different nominal sizes

- wear-free measurement

- fully welded, no seals

- combinable with controller MDS-PLC

Characteristics

- compact design

- direct measurement of mass

- Measurement of non-conductive and conductive liquids

- high accuracy / repeatability

- no moving parts

- easy to clean compared to piston filler

- gentle product filling

- Chemistry and pharmaceutical

- Food and beverage

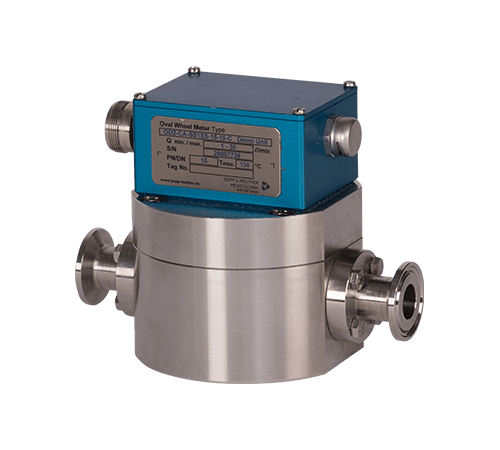

OD

Application:

The focus is on the measurement of non-conductive liquids. This meter is designed for the measurement of e.g. oil or demineralized water. Due to the measuring principle, an inlet or outlet section is not required.

Technical Data

| Nominal size | DN10,DN15,DN25 |

| Process connection | TriClamp according to DIN 32676 |

| Material |

Housing: stainless steell Oval wheels: stainless steel, PEEK Seals: EPDM, alternatively Viton |

| Flow Range |

0.2 to 5 l/min – 2,000 Pulses/ 1 to 30 l/min – 1,000 Pulses/l 2 to 50 l/min – 400 Pulses/l 4 to 100 l/min – 200 Pulses/l |

| Accuracy | ±0,25% to ±0,5% |

| Repeatability | ±0,1% |

| Viscosity | 0,3 to 1.500 mPa·s |

| Process temperature | Liquid temperature: -10°C to +130°C (-14°F to 266°F) ambient temperature: -20°C to +70°C |

| Process pressure | max. 16 bar |

| Ex-protection |

no |

Special features

- Fillings from 10 ml possible

- very short dosing times > 250ms

- high resolution (e.g. DN10: 2000 pulses/l)

- large selection of filling quantities with different nominal sizes

- can be combined with the batch controller

Characteristics

- direct measurement of volume

- measurement of non-conductive and conductive liquids

- high accuracy / repeatability also for small quantities

- high long-term stability

- Chemistry and pharmaceutical

- Food and beverage

Controllers

Compact dosing control

Series MDS-PLC

Application:

The field of application of the MDS-PLC is the control of meters and valves in small filling machines. The MDS-PLC configures the parameters and settings, visualizes the data and controls the valves.

By using this compact controller, manufacturers can quickly integrate the dosing functions into their filling machines. No additional PLC is required. The compact controller is operated via the external inputs or via the touch screen. All accuracy functions are integrated in the compact controller, even if a cost-effective PLC is used for other purposes in the filling machine.

Technical data

| Inputs | 4 counting inputs 4 Start input 4 Stop inputs 1CIP input |

| Outputs | 4 Valves outputs 0.2 A 4 Tolerance output 4 Outputs for closing the valve |

| Power supply | 24 VDC (20-28V) |

| Flow range | up to 3,000 m³/h |

| Temperature range | 0°C bis +50°C (32°F to +122°F) |

| Display | colour touch screen 320 x 240 Pixels |

| Size | 170 x 135 x 80 mm |

Special features

- 4 counting inputs 100 kHz

- 4 valve outputs

- suitable for fast filling applications

- with overflow correction and max. dosing time switch-off

Characteristics

- for 4 counters such as electromagnetic flowmeters, mass flowmeters, oval wheel meters or others with pulse output

- color touch panel

- many functions from 30 years of experience in filling applications

- Chemistry and pharmaceutical

- Food and beverage